Your Best Value in Complete CAD/CAM

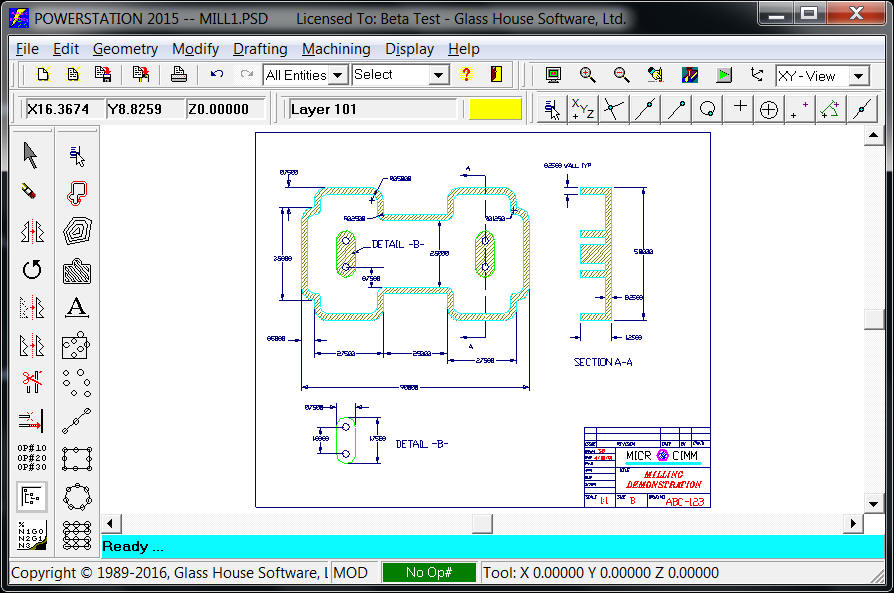

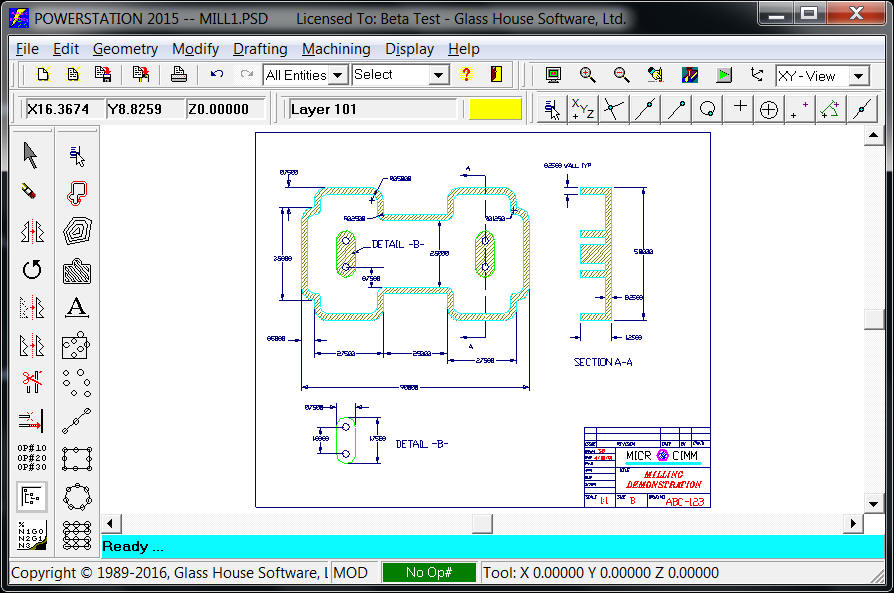

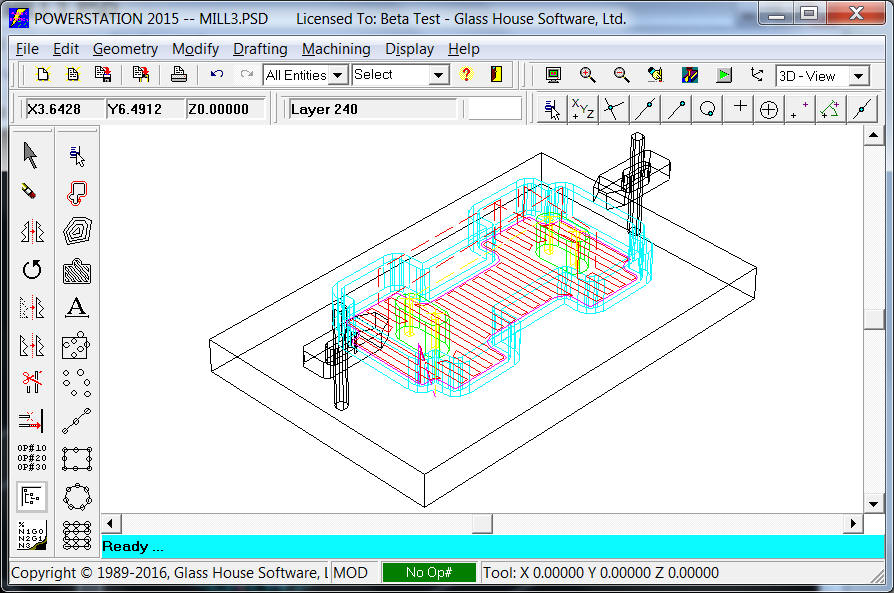

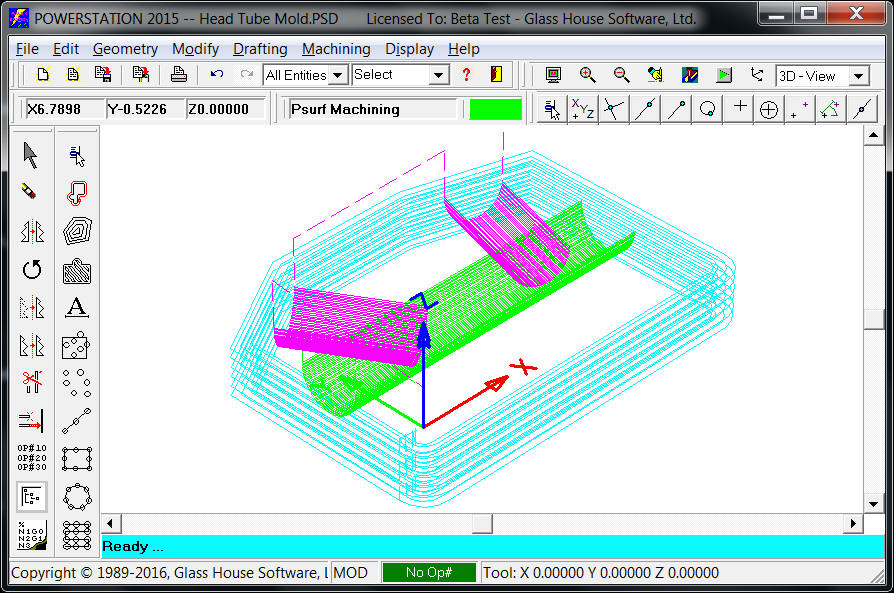

POWERSTATION is a fully integrated 2-1/2 - 3 axis

CAD/CAM system.

One system can program your CNC Milling,

Turning, EDM, Laser, Plasma, Waterjet machines, without any additional cost.

Complete tutorials, documentation, and technical support make

this affordable, proven software an outstanding value.

Download More Information, Videos and a Demo of POWERSTATION

Mills, Lathes, EDM's, Laser, Plasma, Waterjet (Punch with optional POWER-FAB)

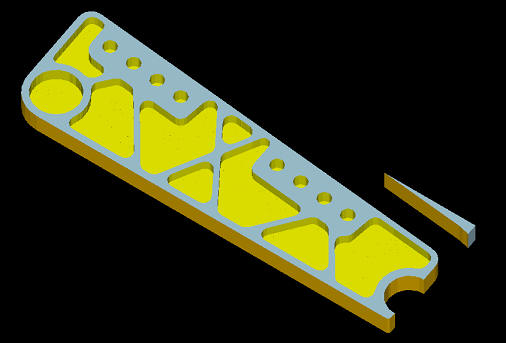

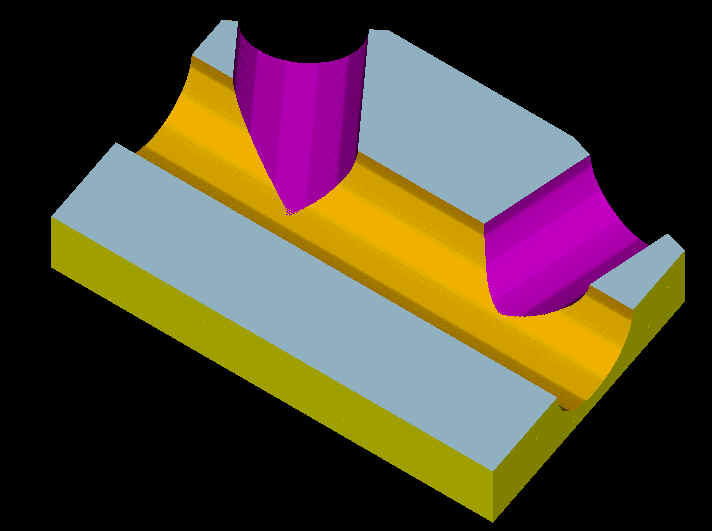

Solid Verification - Solids verification on both tool path creation and final -G- codes.

If a system is powerful but its power cannot be tapped, it is useless. If a system is simple to use, but its power limited, your business can suffer. Ease of use is an often abused term in the computer industry today.

WORK AT YOUR LEVEL

Commands can be entered by simple mouse - menu selection or by shortcut keyboard commands. These two methods can be freely intermixed, providing an optimum user interface tailored to the way that you think and work. For example: in many cases you will be asked to indicate with the cursor the approximate location of a blend radius or tool position. The system will take this location and calculate the exact position automatically.

Shop people are machinists and mechanics not computer programmers. Shop people want to get in, create a good, verified program and get back to the business of doing what they do best; making parts.

On-line, hypertext help is always a keystroke away. You simply point and click on the topic in question. The system will give information on the topic and automatically display related topics.

All prompts are written in simple shop English not "computerese". Practical defaults to all questions speed job creation.

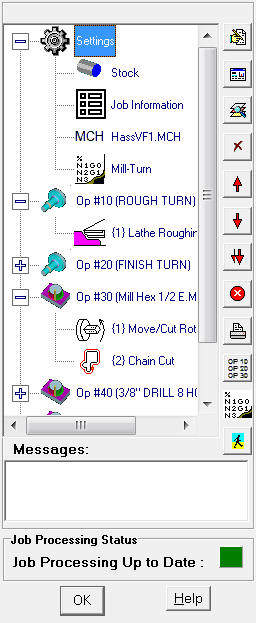

"ASSOCIATIVITY" HAS ONLY BEEN AVAILABLE IN CAD/CAM PROGRAMMING SYSTEMS COSTING OVER $8,000 NOT ANYMORE !!!

Now, When You Need To Change Your Tooling, Part Geometry, Or Any Other Engineering Revision Is Called For, POWERSTATION - PRO/PRO+ With Full "Associativity" Can Automatically Re-Generate All Your Toolpaths... Easily, Quickly, and Affordably.

** "Associativity" Featured in POWERSTATION PRO & PRO+ Versions Only!!

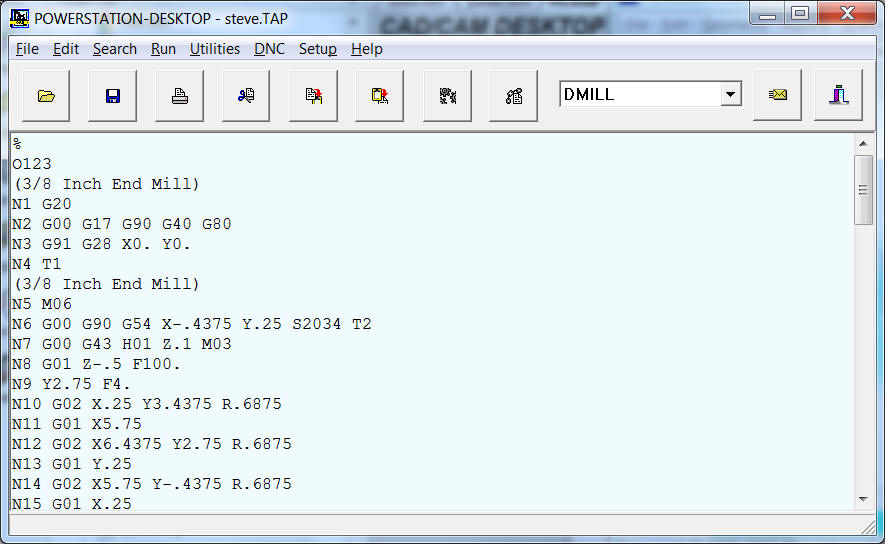

NC-CODE GENERATION (POST-PROCESSING)

An extensive library of over 130 pre-written post processors is supplied on your system CD-ROM at no additional charge. Use these posts as is, or customize them to meet your specific needs.

Included in POWERSTATION is a generalized post processor that provides the ability to "teach" the system attributes of each of your current and future machines.

By answering simple questions pertaining to : G & M codes, number formats, etc., the generalized post automatically creates and maintains a parameter file for that specific machine.

Once created, these files are automatically retrieved and used by simply specifying the machines name.

Post macros: The post macro feature allows for simple customization of the post processor output. Basically an operator defines a post macro by painting a picture of the desired output and assigning a name to this information. Unlike many systems where this information is static and unchanging, POWERSTATION post macros are dynamic and can make logical decisions based on the current machine status.

This flexible system has been customer tailored to a broad range of NC/CNC machine tools, from old hard wired NC-chucker lathes to modern multi-axis CNC machining centers.

Partial List of Sample Posts Included (Not in order!):

Acrolock EZ-Track Seibu EDM Agietron Fanuc (all models) Servo 3000 AhHa Fadal Traub lathe (Live tooling) Analam Haas Trionics Bandit (old/new) Heidenhein (Native or -G- Code) Yasnac (all models) Bendix GE-550 Omni-Turn Bridgeport (Including Old Tab Sequential) Hurco (-G- Code or Conversational Print out) Shopbot Robotics Centroid Meldis Delta Tau Cincinati Milltronics Millstar Crusader OKK Flashcut Dynapath Okuma IBH Automation PA 8000 Dynamyte Prototrak Mill Power Mazak Tree Hardinge Monarch Sodik Hansvedt EDM Burny Thermwood Japax Concepts 4 Progress Microkinetics Mill Master Pro Precix Fagor Power Automation Flow Waterjet Shop Saber Router Hybrid 6 Num Acu-Rite Artsoft MACH3 NEE Control Charmilles KIA Lathe EZ-Path TOSHIBA WINCNC Milling Doosan Googolplex Seimens Sherline Digital Router Komo Router Tormach mill/turn GRBL Googolplex Laser Amada Laser Toshiba / Tosnac Allen Bradley Behrens Laguna Mill / Router UGS Tree Dynapath Sharp Milling Linux CNC Lathe

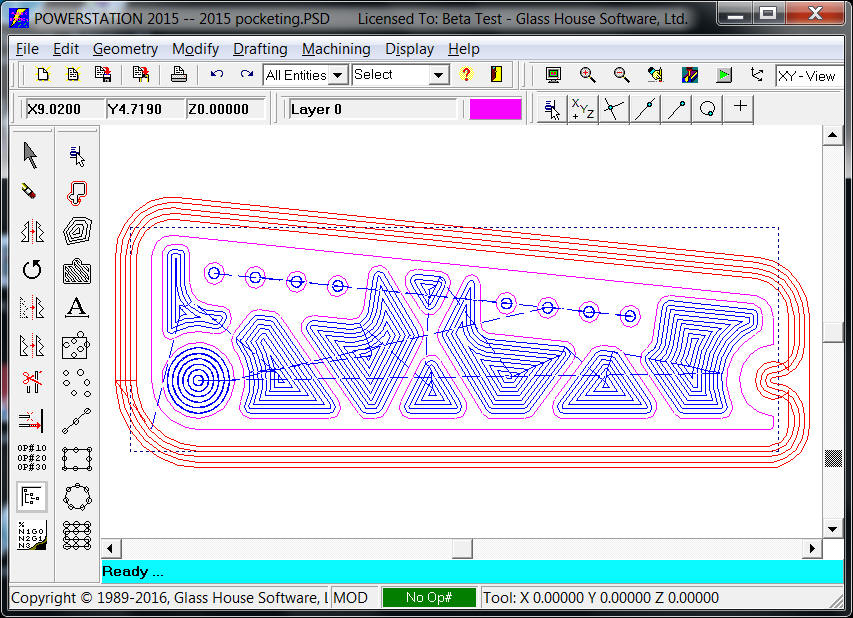

Pocketing, Finish Contouring, Drilling

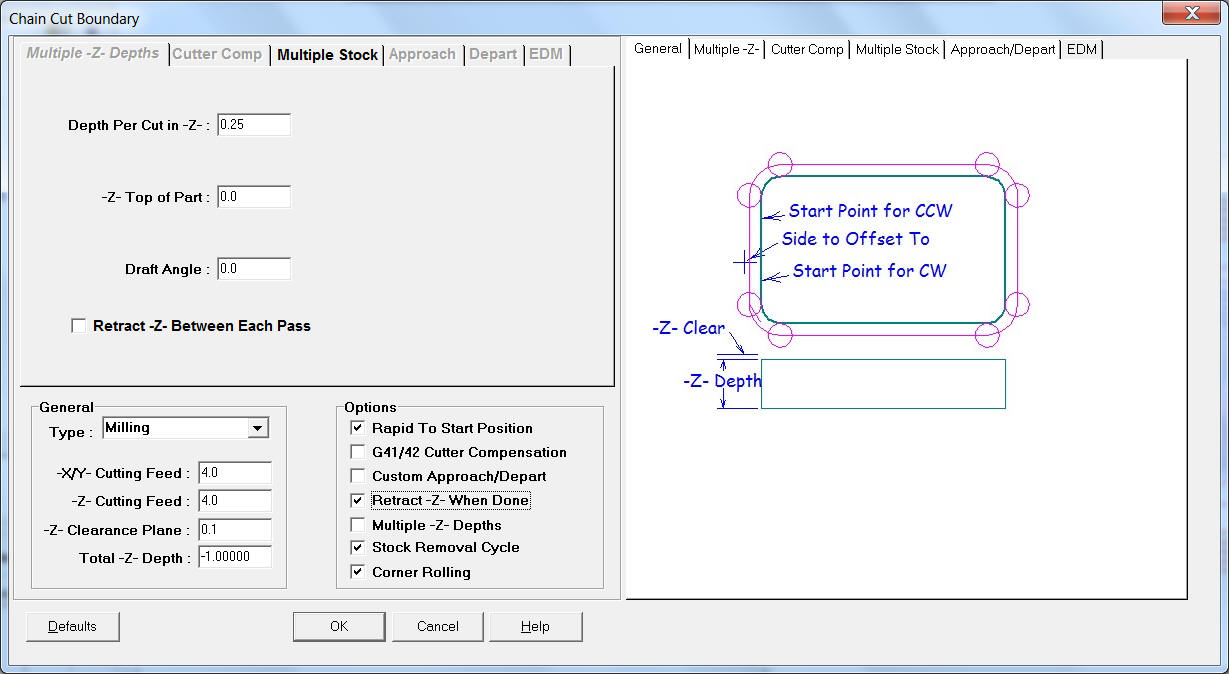

Typical Machining Dialog Box

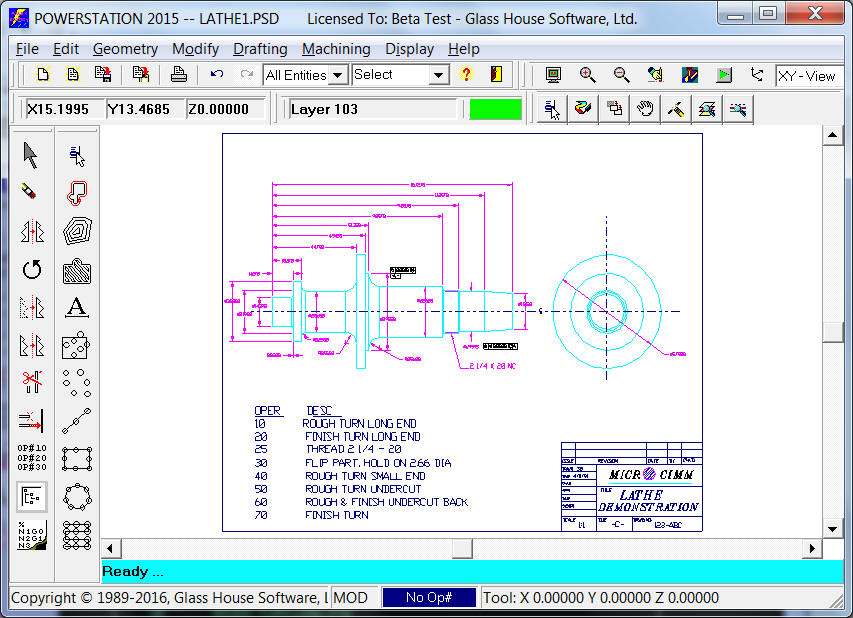

Lathe Part Print

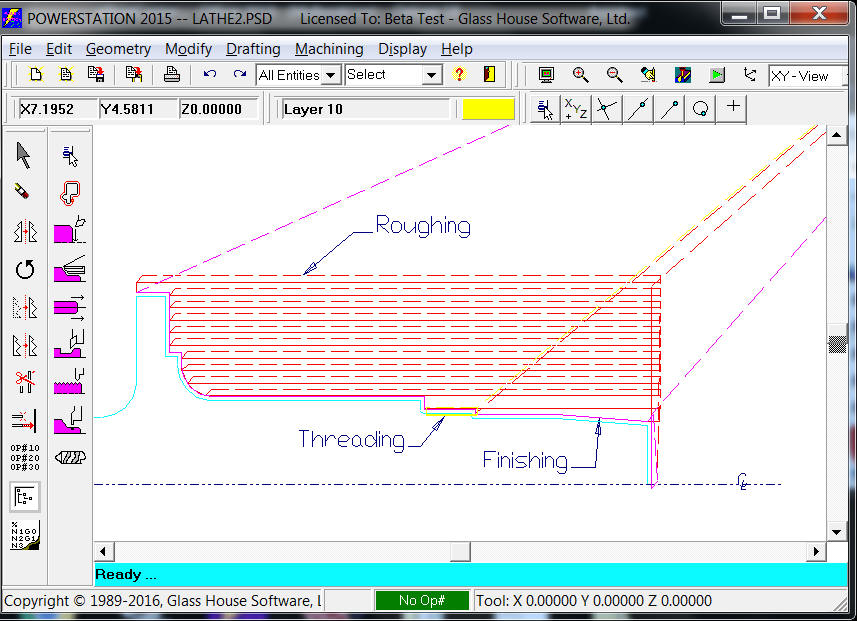

Roughing, Finishing, Threading

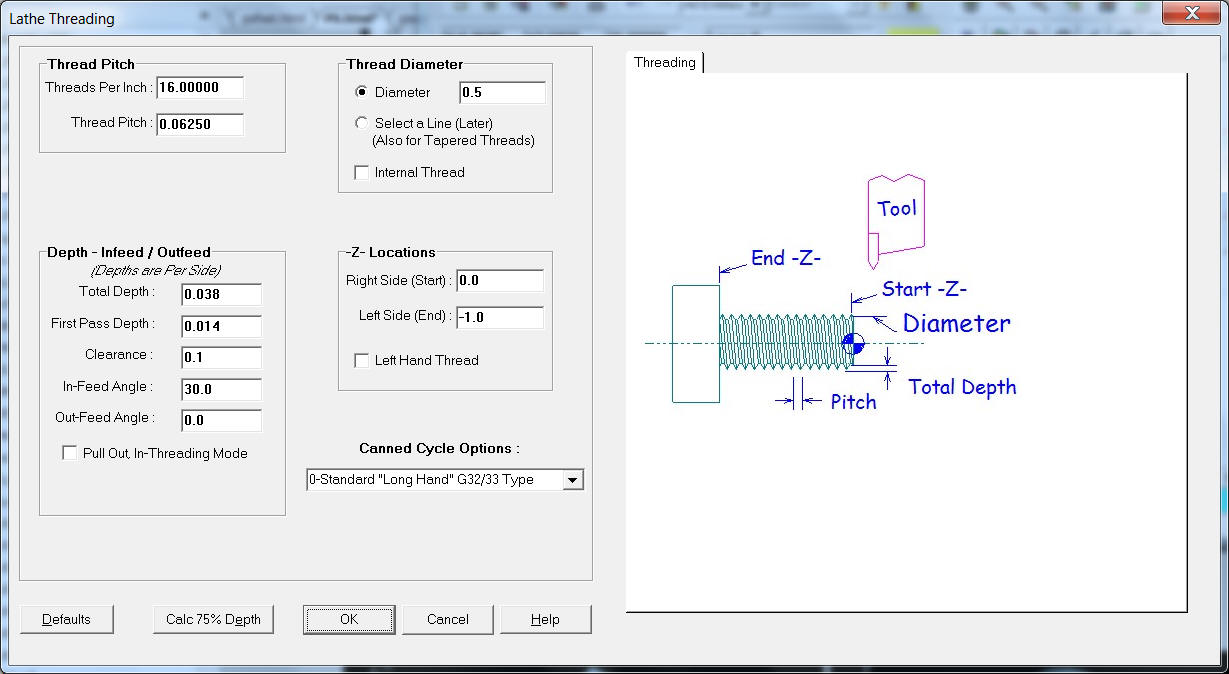

Sample Threading Dialog

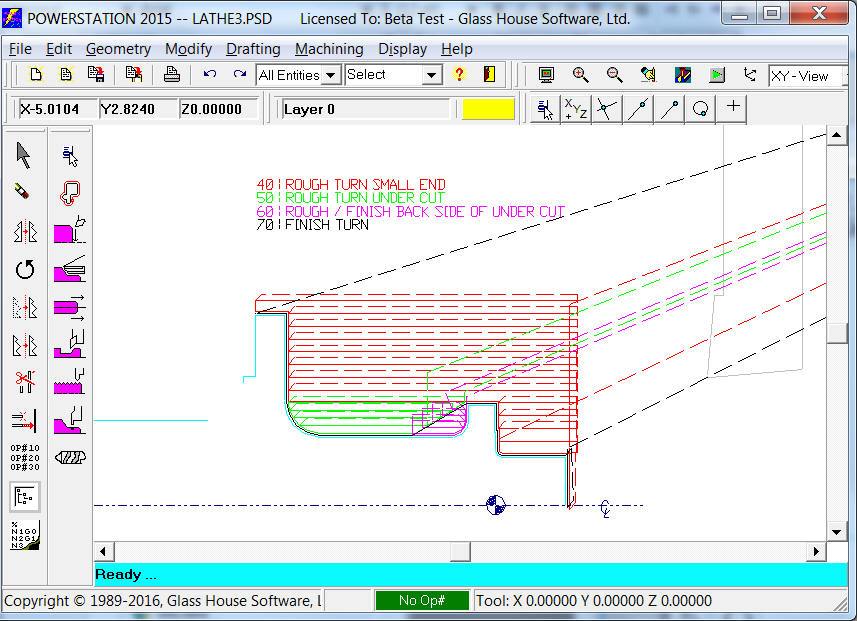

Lathe Roughing, Undercutting, Back Turn Undercutting, and Finishing

Minimum System Requirements: